Case Studies

Automating Your Technology™

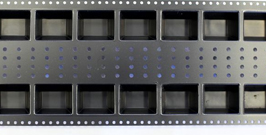

Development of a Continuous Tape Solution for Flat-Head Pins

Problem:

A manufacturer of alarm systems needed an automated method to package, store, transport, and load custom flat-head pins for final assembly. We were tasked with the development of an effective, automated packaging solution for this line of custom pins. The system needed features such as a very small footprint, automated packaging, and unloading, and provide protection for the pins during storage and transit to their assembly factory.

Solution:

We developed a very unique continuous tape solution, which was tailored specifically to this application. We designed a custom in-line punch die producing holes in multiple rows that are precisely sequenced for an automated assembly process. The form die was also designed with spacer wells to protect the packaged product. We utilized the tape to package the pins close together in order to save on material, but still work with maximizing the speed of their pick and place machine. The pins were then covered with KEAPAK™ cover tape before the pocket tape is loaded on to KEAPAK™ 13″ Reels keeping the pins secure and consistently in place ready for immediate unloading without any additional processes. To learn more about this project, or the processes used to develop it, see the table below or contact us directly.

| Product Name | Continuous, Custom Punched Pocket Tape |

| Product Description | Continuous pocket tape with multiple rows of holes with protective side-wells. |

| Capabilities applied/Processes | Requirements :

Process:

|

| Equipment/Products Used to Manufacture Systems | Inline, precision thermoforming machine with a custom punch |

| Overall Part Dimensions | 72mm wide pocket tape |

| Tightest Tolerances | +/- .1mm |

| Material Used | .45mm thick x 72mm wide – KEASTAT™ I.S. Polystyrene |

| Material Finish | Matte Finish to reduce glare for vision systems |

| In process testing/inspection performed | 100% pocket inspection w/ measurements logged & lot traceability |

| Industry for Use | Industrial |

| Volume | 320,000 units released per shipment |

| Delivery/Turnaround Time | 2 Weeks ARO |

| Delivery Location | Assembled in the US and distributed worldwide |

| Standards Med | Customer Specifications |